|

This is the housing and (possibly original) bearing that supports the gearbox input shaft spigot. The only time that this can be replaced is when the crankshaft is removed from the engine and the flywheel has been detached. Don't miss the opportunity. |

|

A new bearing installed. Note that this is grease filled and is fitted with both seals because this is one of the few bearings that receives no lubrication during its working life. The two small threaded holes are used to locate bolts when dismantling the housing from the flywheel. |

|

There are 8 x 1/4" drainage holes in the rear face of the flywheel. They empty the oil catcher ring on the inside. Note the angle. These holes can become clogged with a mixture of dirt, oil and dust from the clutch linings. Make sure that they are cleaned out. |

|

The are a further 8 x 1/4" holes drilled in through the body of the flywheel. Again, these should be cleaned to ensure satisfactory drainage. Note the collar on the nearest stud. There is a matching item opposite, both of which ensure that the clutch assembly is fitted with the correct orientation. |

|

One of the many markings on the periphery of the flywheel. This instruction relates to the gap setting to be used on the number 1 valve when assembling the timing gears and setting the valve timing. |

|

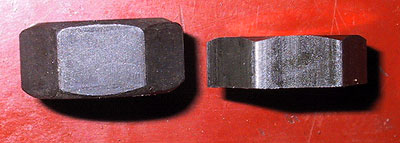

An important difference. As will be seen on the next page, the nuts used to attach the flywheel are half-thickness when compared to standard items. These nuts were used on all Small HP flywheels up to the end of series F2. |